| Model | 3015 | 4020 | 6015 | 6020 |

| Working size | 3000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm |

| Max moving speed | 100m/min | |||

| Max acceleration | 1.0G | |||

| Positioning accuracy | 0.05mm | |||

| Repetition positioning accuracy | 0.03mm | |||

| Power of laser | 4000W/3000W/2000W/1500W/1000W | |||

The above data is for reference only and is subject to the actual product.

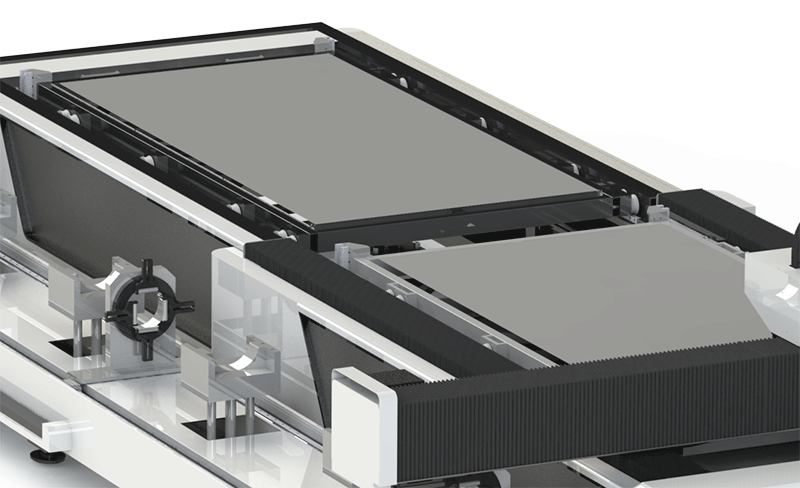

Realize the comprehensive positioning of guide rail, with high quality machining process

Stable machining accuracy and efficient cutting ability

Gear rack transmission system with good rigidity and higher precision;

The feeding time is reduced, and the rigidity and precision of the drive mechanism are significantly better than the conventional mechanism

Provide real-time pressure value

When the pressure value is lower than a certain value which goes into good cutting effect and accuracy, the abnormal information is pushed

Real-time monitoring and early warning protection for worktable and alternative worktable Automatic lubrication, automatic worktable switch, and other functions. Support origin saving

Linear guide rail High load carrying capacity in four directions makes the linear guide rail with ultra-high load carrying capacity Low noise design Improves smoothness and reduces frictional resistance Ultra-high rigidity in four directions, high-precision machining at high speedAutomatic zoom laser cutting head The laser head is adjusted with two-point alignment, and the focus adjustment is driven by imported motor. In terms of perforation, the efficiency is significantly improved. The lens are protected in drawer type for easy replacement

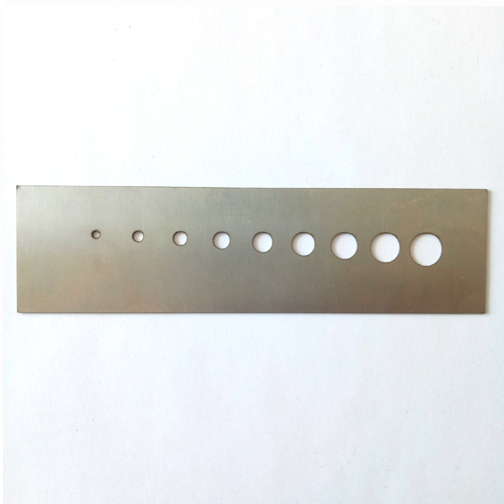

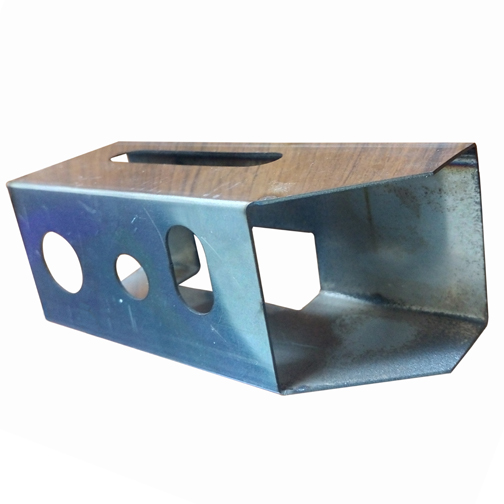

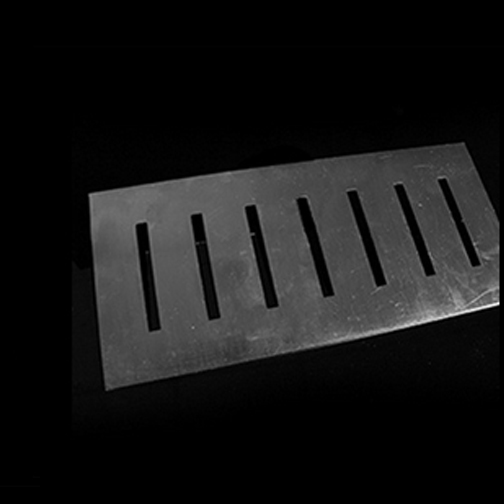

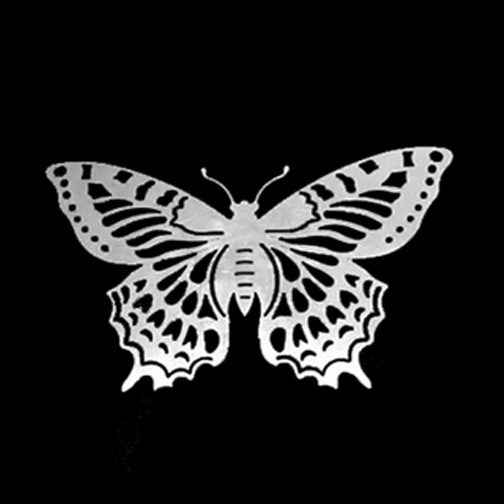

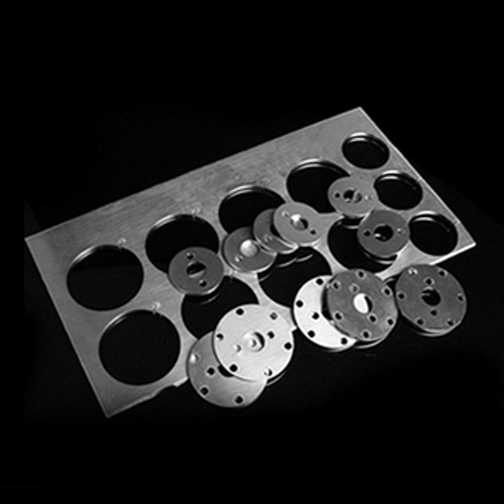

Suitable for cutting metal plates and all kinds of metal pipes Support the functions such as scanning cut, frog jump, automatic edge-tracking, common edge cutting, breakpoint return, follow-up control, going back. Cutting materials: High-reflective materials such as carbon steel, stainless steel, alloy steel, silicon steel, galvanized sheet, copper and aluminum, as well as square tube and circular pipe

Intelligent travel protection Automatically monitors the traveling range of the motion module, responsively and quickly.At the same time the risk of operation is reduced to the lowest with a hard limit as a additional safeguard

Intelligent control software Intelligent layout for cutting graphics;Multi-type graphics import;Automatic optimization of cutting sequence; Intelligent edge-tracking, automatic positioning;Improve the utilization of materials, reduce waste; Simple and fast system operation, accurate cutting instructions, making better user experience

Intelligent alarm system The multi-directional abnormal alarm of the device is directly transmitted to the panel, the device fault is known in advance, and the hidden danger is reduced, make the equipment abnormal troubleshooting efficiency doubled

with modern production workshop and necessary equipments

Nowadays, with the increasing development of science and technology, as a mature CNC equipment manufacturing enterprise, VIOOO Laser will continue to adhere to the business philosophy of “survive by quality, develop by reputation”, the management attitude of“rigor and pragmatism”, and the mission of improving production efficiency by technological innovation, to provide customers with better CNC equipment and solutions.

VIOOO Laser is on the way to success.You are on the way to success too accompanied by VIOOO Laser.