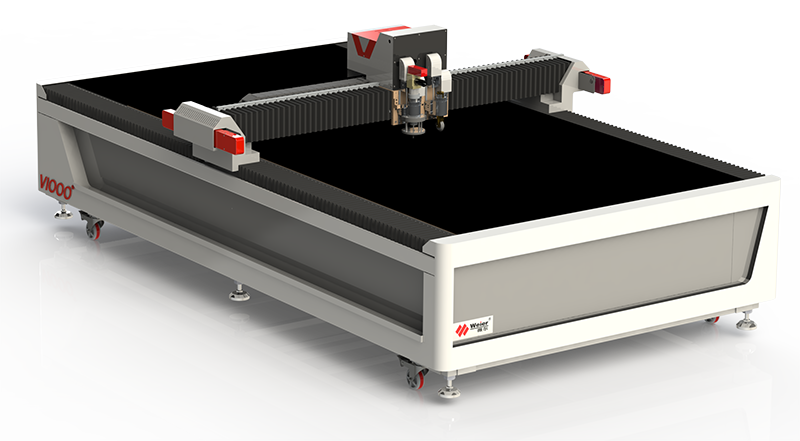

| Model | 1625 | 1825 | 2035 | 2240 | Customizable (length*width) |

| Effective cutting size | 1600mm*2500mm | 1800mm*2500mm | 2000mm*3500mm | 2200mm*4000mm |

length: 800mm-15000mm Width: 800mm-5000mm |

| Feeding mode | manual/automatic | ||||

| Max cutting speed | ≤1500mm/s | ||||

| Cutting precision | ±0.05mm | ||||

| Max cutting thickness | 50mm | ||||

| Data format | DXF, PLT, AI, etc. | ||||

| Transmission mode of data | networking cable, data line, USB disk | ||||

| Materials fixation | vacuum adsorption | ||||

| Power of vacuum pump | 7.5kw/9kw/11kw | ||||

| Working voltage of main machine | AC220V/50HZ | ||||

| Working voltage of vacuum pump | AC380V/50HZ | ||||

| Rated power | 10KW-13.5KW | ||||

| Cutting tool | high frequency oscillating knife | ||||

| Optional tools | oscillating knife full Cutting tool, high power active circular knife tool, punching tool, pneumatic oscillating knife tool, drag knife tool, half Cutting tool, V-cut tool, ball-point pen tool, creasing tool | ||||

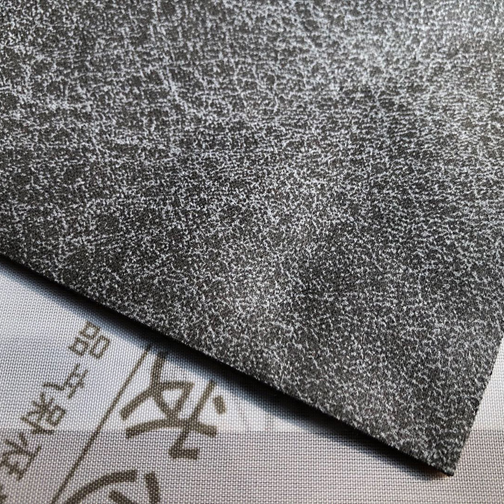

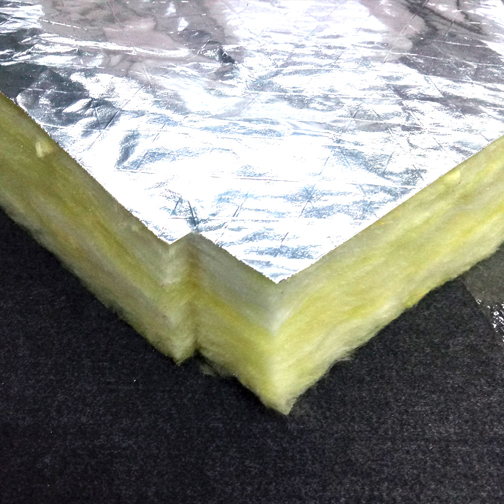

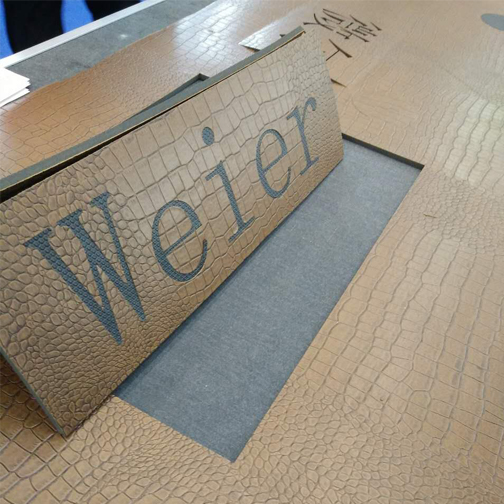

| Applicable materials | Non-metal materials including car mat, cloth, PE foam, fiber glass, corrugated cardboard, carton, soft PVC crystal mat, leather, sponge, advertising materials, composite materials, etc. | ||||

| Applicable industries | advertising, carpet, garment, fabrics, automotive interiors, suitcases and bags making, packaging, sound-proofing, etc. | ||||

The above data is for reference only and is subject to the actual product.

design concept of replaceable tool

no need to make a die, directly import the electronic version

no pollution due to mechanical cutting

multi-machine working simultaneously supervised by one person

up to 0.05mm

able to cut a variety of flexible materials and special soft materials

The precision cutting assembly is developed and manufactured by ourselves, working with the steel and aluminum adsorption platform of VIOOO Laser, result in full, stable, and accurate cutting effects

The positioning accuracy, repetition accuracy and reverse clearance of X, Y and Z axes of the machine were all detected by laser interferometer.

The professional software special for carton cutting jointly developed by DOOSON co., ltd. of South Korea and VIOOO realizes the one-key generation of various carton patterns, working together with our oscillating cutting machine, which facilitates producing higher quality products.

Equipped with a variety of tools such as oscillating knife, creasing wheel, the machine can achieve many functions including cutting and creasing wheel, etc.

Product appearance: V+ series oscillating knife cutting machine is equipped with luxurious metal shell, which can better protect the internal motion system and circuit structure of the equipment, and make the equipment more beautiful and elegant

Control system: The intelligent control system, PLC programming control system, work together with automatic typesetting and drawing softwareare, to solve the special needs that cannot be processed by ordinary equipment.

Motion system: servo motor, quality guide rail, doubl drives on Y axis, suitable for high precision machining.

Structural system: high strength welded frame, stable and no jitter when running

Protection system: the system is upgraded with high-sensitivity infrared induction safety protection device to effectively protect operators

With modern production workshop and necessary equipments

Nowadays, with the increasing development of science and technology, as a mature CNC equipment manufacturing enterprise, VIOOO Laser will continue to adhere to the business philosophy of “survive by quality, develop by reputation”, the management attitude of“rigor and pragmatism”, and the mission of improving production efficiency by technological innovation, to provide customers with better CNC equipment and solutions.

VIOOO Laser is on the way to success. You are on the way to success too accompanied by VIOOO Laser.